“How to easily and economically functionalize composite parts to help their democratization in the automotive mass production?”

BENEFITS GENERATED BY GAMING FASTENERS DESIGNED FOR COMPOSITE

Composite parts functionalized with

_ no impact on production rate

_ no impact on the manufacturing cost!

Other benefits:

- One-shot solutions

- No labor cost due to fasteners setting

- No investments to set fasteners

- Optimization of performance thanks to the

- Reorganization of fibers around fasteners (Organosheet fibers uncut)

- Precise locating of fasteners managed in mold

- Perfectly flush inserts.

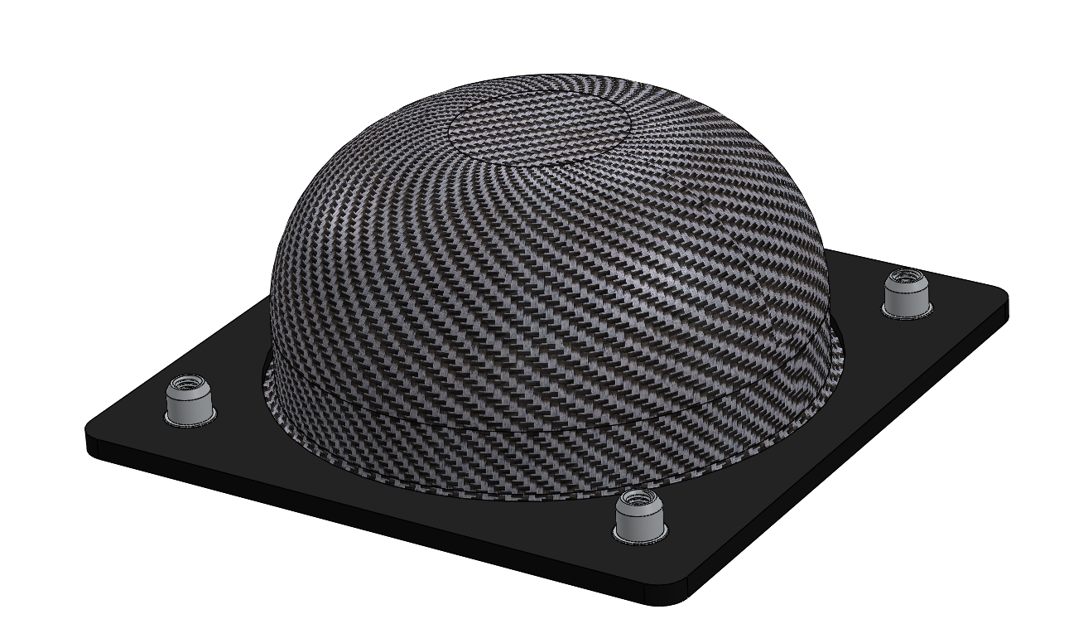

Structural insert

Designed for composite parts

Application:

Fastening functionalization one-shot for

lightweight composite parts

In Mold FASTeners

Designed for composite parts

Application:

Fastening functionalization one-shot for

lightweight composite parts

Compression limiter

Application:

Fastening functionalization for lightweight

composite parts

Electric Resistance Welding INsert

Application:

Fastening solutions for multi-material

assemblies

EXAMPLE OF APPLICATION :

AUTOMOTIVE CROSSMEMBER :

Composite materials & process:

Crossmember has been redesigned for metal substitution by a «hybrid» composite plastic solution based on a one shot process using a continuous fiber plate overmolded by polyamide.

Benefit of using composite:

The benefit is a mass saving of 45% for the function, compared to metal solution. A “zero waste” approach based on cutting optimization and in application recycling has been followed.

Description:

The product main interest is a large thin panel with a deep stamped area and management of local reinforcements in order to optimize the mass. This product illustrates a large semistructural panel which has a high potential in all automotive bodyworks supports especially in the front of the car where light weighting and energy absorption are highly requested.