“Multi-material designs : the new rules in automotive industry.”

Main targets:

Light weight & Mass reduction:

- Low consumption,

- Reduction of emissions,

- Autonomy improvement (In particular of electric vehicles),

Structural reinforcement & Architecture evolutions,

- Dynamic performances improvement

- Adaptation to new safety standards,

Reduction of numbers of parts,

- By using plastic or composite parts which enable to replace several metallic pieces into one

If the multi-material designs are a source of large optimization of the automotive performances, there implementation in practice is obstructed by technical assembly difficulties & economical issues.

The current fastening characteristics aren’t in line with automotive industry’s targets,

in particular the strong will of challenging the multi-material assembly …

_ without making big industrial investments,

_ without revolutionizing the organization of Body In White workshop.

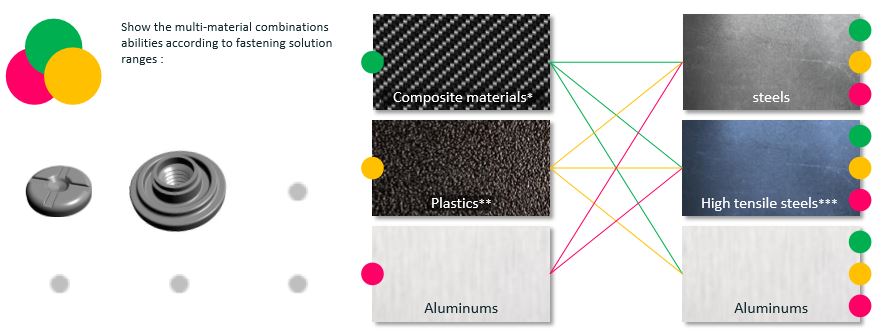

ERWin

Electric Resistance Welding INsert

Application:

Fastening solutions for multi-material

assemblies

ERWin +

Electric Resistance Welding Insert With additional anchoring point

Application:

Fastening solutions for multimaterial assemblies & one-shot functionalization for lightweight composite parts

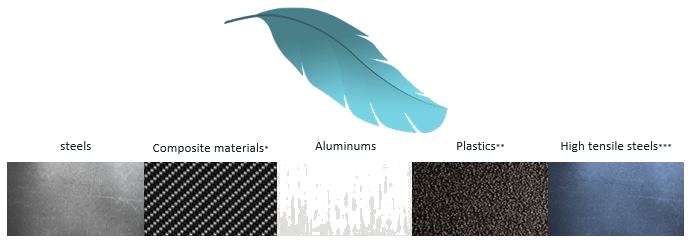

*

Composite materials: based on thermoplastic or thermosetting matrix, with long fibers reinforcement, structured or not.

**

Plastics: injected with no reinforcement or with short reinforcements.

***

New generations of steel with high performances.